Aerospace Precision Machining in USA

Introduction: Panank Enterprises’ Mastery in CNC, Fabrication & Beyond

In the high-stakes aerospace industry, precision, reliability, and innovation are non-negotiable. As companies seek the most advanced and precise machining solutions, Panank Enterprises has emerged as a leader in aerospace precision machining in the USA. With cutting-edge CNC technology, superior fabrication capabilities, and a commitment to exceeding industry standards, Panank Enterprises has become the trusted partner for leading aerospace manufacturers.

The Importance of Aerospace Precision Machining

Aerospace components require the highest levels of precision due to the extreme environments and safety-critical nature of the industry. Every component must meet stringent tolerances, often measured in microns, to ensure optimal performance and regulatory compliance. From aircraft engines to structural components, precision machining is essential for achieving reliability and longevity in aerospace systems.

Key Factors in Aerospace Machining

- Tight Tolerances: Aerospace parts must adhere to exact specifications to maintain functionality and safety.

- Advanced Materials: Aerospace applications often involve titanium, Inconel, and other exotic metals that require specialized machining expertise.

- Regulatory Compliance: The industry is governed by stringent quality certifications such as AS9100, ISO 9001, and NADCAP.

- Innovation & Technology: Advancements in CNC machining, automation, and digital manufacturing drive continuous improvements in precision and efficiency.

Panank Enterprises: A Leader in Aerospace CNC Machining

Unparalleled CNC Machining Capabilities

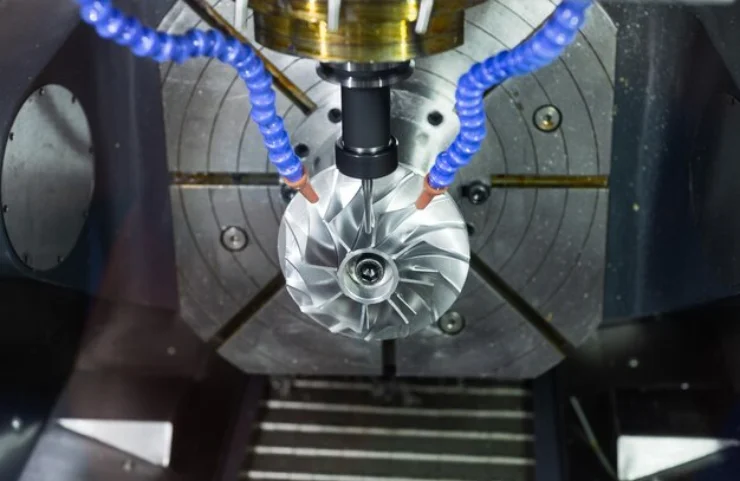

Panank Enterprises has positioned itself at the forefront of CNC machining by leveraging state-of-the-art multi-axis machining centers. These advanced machines enable the production of complex aerospace components with unmatched precision and efficiency.

Benefits of Panank Enterprises’ CNC Machining:

- 5-Axis CNC Machining: Allows for intricate geometries and reduced setup times.

- Automated Quality Control: Ensures repeatability and adherence to tight tolerances.

- High-Speed Machining: Reduces lead times without compromising precision.

- Customized Solutions: Tailored machining approaches for unique aerospace applications.

Fabrication & Sheet Metal Expertise

Beyond CNC machining, Panank Enterprises excels in precision fabrication and sheet metal manufacturing. Aerospace structures require lightweight yet robust components, and Panank Enterprises delivers high-quality fabricated parts that meet the most demanding industry requirements.

Fabrication Services Include:

- Sheet Metal Forming – Producing lightweight, aerodynamic components.

- Precision Welding – AS9100-certified welding for aerospace structures.

- Assembly & Integration – Seamless integration of multiple fabricated components.

Advanced Materials & Manufacturing Processes

The aerospace industry relies on materials that withstand high temperatures, stress, and corrosion. Panank Enterprises specializes in machining and fabricating a range of aerospace-grade materials, including:

- Titanium & Titanium Alloys – Known for their strength-to-weight ratio.

- Aluminum Alloys – Lightweight and corrosion-resistant.

- Inconel & Superalloys – Ideal for high-temperature aerospace applications.

- Carbon Fiber & Composites – Used in advanced structural components.

Quality Assurance & Certifications

Panank Enterprises adheres to the strictest quality control measures, ensuring every part meets the highest aerospace standards. The company maintains industry-critical certifications, including:

- AS9100 Certification – The aerospace industry’s gold standard for quality management.

- ISO 9001 Compliance – Ensures consistent manufacturing excellence.

- NADCAP Accreditation – Verifies superior special process capabilities.

Custom Aerospace Machining Solutions

Panank Enterprises understands that aerospace manufacturers require specialized machining solutions tailored to their unique applications. The company collaborates with clients to develop custom machining strategies that meet exact design and performance requirements.

Tailored Machining Capabilities:

- Prototype Development – Rapid prototyping for aerospace innovation.

- Low-Volume & High-Volume Production – Scalable solutions for varying production needs.

- Precision Tooling & Fixtures – Custom tooling to enhance production efficiency.

- Component Reverse Engineering – Engineering support for legacy parts and system improvements.

Industry Applications of Aerospace Machining

Panank Enterprises serves a wide range of aerospace sectors, delivering precision components for critical applications, including:

- Commercial Aviation – Machined parts for aircraft structures, engines, and avionics.

- Defense & Military Aerospace – High-performance components for defense aircraft and weapon systems.

- Space Exploration – Precision machining for satellites, space vehicles, and propulsion systems.

- Unmanned Aerial Vehicles (UAVs) – Lightweight, durable components for UAVs and drones.

The Role of Automation & Smart Manufacturing

Panank Enterprises integrates automation and smart manufacturing techniques to enhance production efficiency and precision. By leveraging Industry 4.0 technologies, the company ensures continuous process optimization and data-driven quality control.

Key Automation Innovations:

- Robotic Machining & Handling – Reduces human error and enhances precision.

- Real-Time Data Analytics – Monitors production variables to ensure consistent quality.

- AI-Driven Predictive Maintenance – Reduces downtime and enhances machine performance.

- Digital Twin Technology – Simulates machining processes to optimize outcomes before production.

Sustainability & Green Manufacturing in Aerospace Machining

As the aerospace industry moves towards more sustainable practices, Panank Enterprises is committed to reducing its environmental impact.

Sustainable Practices:

- Energy-Efficient CNC Machines – Reducing power consumption while maintaining performance.

- Waste Reduction & Recycling – Implementing programs to minimize material waste.

- Eco-Friendly Coolants & Lubricants – Using biodegradable and non-toxic machining fluids.

- Carbon Footprint Reduction – Optimizing operations to lower emissions and resource use.

Future Trends in Aerospace Machining

The aerospace industry continues to evolve with new technological advancements. Panank Enterprises stays ahead of the curve by adopting and investing in emerging trends.

- Additive Manufacturing (3D Printing) – Expanding possibilities for lightweight aerospace components.

- Hybrid Manufacturing – Combining traditional machining with additive processes for efficiency.

- Digital Manufacturing & IoT Integration – Enhancing real-time monitoring and smart factory capabilities.

- Next-Generation Materials – Exploring ultra-lightweight and high-strength alloys.

Why B2B Aerospace Buyers Trust Panank Enterprises

For aerospace manufacturers seeking a reliable, U.S.-based machining partner, Panank Enterprises offers distinct advantages:

- Proven Expertise – Decades of experience in aerospace machining and fabrication.

- Cutting-Edge Technology – Investment in the latest CNC, automation, and digital manufacturing solutions.

- Comprehensive Services – A one-stop shop for precision machining, fabrication, and assembly.

- Commitment to Quality – Stringent quality control and industry-leading certifications.

- Scalability & Efficiency – Capability to handle both prototype and full-scale production needs.

Contact us

📞 Phone: +91 9322386986

📧 Email: sales@panank.com / ceo@panank.com

🌍 Website: panank.com

📍 Location: D-12/Bappa sitaram Ind Estate, K. Narayan Dhumal Nagar, Near Rashmi Bunglow, Walive village, Vasai Phata, Vasai( E), Vasai Virar, Palghar-401208, Maharashtra, India

Conclusion

As the aerospace industry continues to advance, precision machining remains at the heart of innovation and safety. Panank Enterprises has established itself as a premier provider of CNC machining, fabrication, and manufacturing solutions, delivering excellence to B2B aerospace clients across the USA. By combining advanced technology, industry expertise, and an unwavering commitment to quality, Panank Enterprises ensures its customers receive the highest-caliber aerospace components for mission-critical applications.

“Don’t forget to share this post!”

![]()

![]()

![]()

![]()